BACKGROUND

Dedeman Mining is one of Turkey’s leading private mining companies. The company started mining chrome in 1947 and expanded to mining lead and zinc in 1964.

CHALLENGE

Following the devastating Soma mine disaster of 2014, which claimed the lives of 301 miners, the Turkish government introduced new safety regulations for the mining industry. The new regulations require mine operators to have real-time location information and headcounts for all miners that are underground in the mine.

The new regulations put pressure on Dedeman Mining and all other Turkish mines to find a robust enough location-based solution that can withstand the harsh conditions in the mines. Some mines can be up to 400m deep with a range of 5km.

SOLUTION

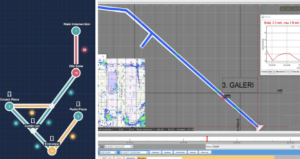

Since 2017, Tagvance has implemented a worker-tracking system in 6 mines owned by Dedeman Mining with an average installation time of 1-2 weeks. 70 Locators were installed throughout the mines, each site being connected to an industrial computer in a secure cabinet via armoured fiber cables. Over 500 trackable tags were installed into the headlamps on workers’ helmets so that no extra equipment is needed and maintenance can be carried out simultaneously for both tags and lamps.

Having evaluated multiple solutions, including Wi-Fi and RF-based technologies, Dedeman Mining decided on Tagvance’s location-based Bluetooth solutions powered by Quuppa, the world leader in advanced location systems, as this solution provides a higher level of location accuracy (less than 10m) at a better price point.

The main selling points for the Tagvance solution were:

- It works even in confined tunnels due to deep radio penetration and map matching.

- It is very flexible and adaptable to the constantly changing needs of mines.

- It has an offline mode which enables use even in emergencies when connectivity is limited.

- The tags have a long battery life of 1-2 years.

- The tags could be attached directly to the headlamps on miners’ helmets.

- The tags allow two-way communication, enabling alerts to be sent to workers underground.

RESULTS

- Dedeman Mining is now fully compliant with safety regulations.

- Workers and managers reported they feel safer knowing there is an RTLS system that can pinpoint their location.

- The same system can also be used for performance measurements of workers and machinery, improving the efficiency of the mines.

NEXT STEPS

Dedeman Mining has started R&D activities to explore how the system can be used for performance measurements for both workers and machinery. The company hopes to optimize machinery maintenance by tracking use times, job order fulfilment by tracking subcontractor behaviour in mines as well as calculations of payable over time by tracking the time spent down in the mines by workers, to name just a few applications.