PDi Digital, an Austrian-based IIoT technology company, aims to revolutionise the ever-evolving industrial landscape by providing reliable low-power digitisation technology to various verticals, including manufacturing, logistics, and healthcare. Their pioneering, modular sepioo® IIoT technology platform enhances process efficiency with key use cases in replacing paper-based labels, automating workflows, and enabling tracking and location-based services.

sepioo®: Reshaping Industrial IoT Processes

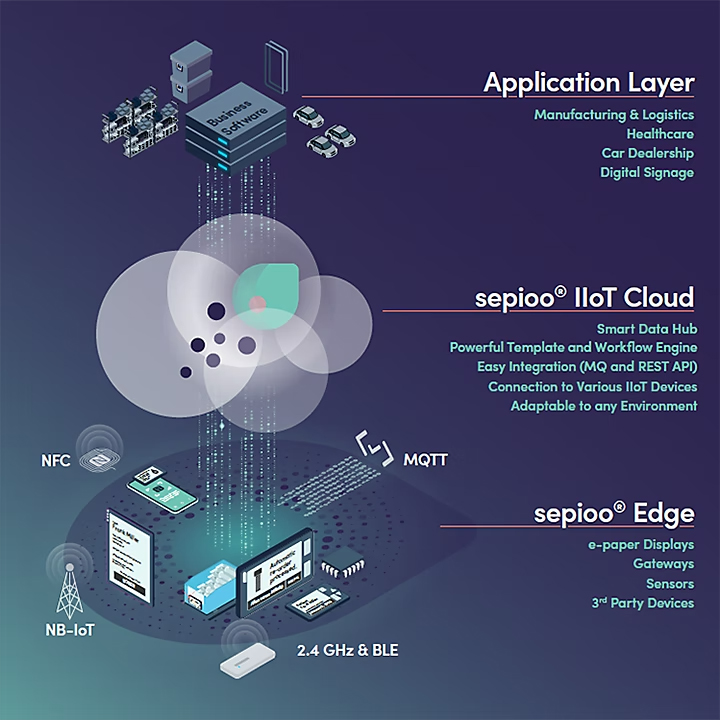

A powerful software and hardware platform, sepioo® is at the core of PDi Digital’s vision to transform fields within Industry 4.0, Smart Factory and IIoT. With its adaptability to any environment, sepioo® seamlessly links various IoT devices, such as displays, scales, sensors, and trackers, to essential business systems like SAP, Sklera, and ARIMS.

Offered as a Software-as-a-Service (SaaS) platform, sepioo® can be up and running in under 5 minutes, with the capability to scale to hundreds of thousands of displays within a single installation. Deploying the sepioo® platform can either be done by leveraging existing infrastructure thanks to the collaboration with leading access point (AP) providers or by opting for a standalone infrastructure offered by PDi Digital.

Digital Displays: Smooth Transition to E-Paper

PDi Digital displays, equipped with button-press control and NFC connectivity, offer adaptable two-way communication across a variety of industrial environments, including manufacturing, logistics, and healthcare.

These displays feature rapid response times and operate with energy efficiency, requiring power only during content updates while remaining maintenance-free for extended periods. They ensure excellent visibility from all angles, even when not connected to a power source. In manufacturing and logistics applications, adopting e-paper displays enhances visibility and control, streamlining processes like smart reordering and data collection, ultimately contributing to improved warehouse management.

Asset Tracking and Location-Based Information Services

With sepioo® displays compatible with the Quuppa RTLS system, organisations can track indoor assets with great accuracy and know their location with sub-meter accuracy. This allows critical information to be displayed directly on these assets using advanced e-paper technology. The platform enables users to set up automated workflows based on specific location-based data, such as triggering actions when objects move or when they enter or exit geofenced areas. This ensures that the right information is delivered to the right place at the right time, enhancing operational efficiency.

Future-proofing Design with Silicon Labs BG22 Wireless SoC

In their pursuit of designing robust display and sensor solutions, PDi Digital actively sought out a reliable wireless vendor to ensure the longevity of their designs and accommodate complex multi-protocol wireless connectivity use cases in various markets. Ultimately, PDi Digital chose the Silicon Labs EFR32 BG22 Wireless SoC due to its power budget with ultra-low transmit and receive power (3.4 mA for TX, and 2.5 mA for RX). With extremely low sleep currents, the BG22 SoC ensured industry-leading energy efficiency, extending the battery life beyond five years. Additionally, BG22 enabled PDi Digital to develop products that are compatible with the Quuppa real-time locating system (RTLS), utilizing the Angle of Arrival (AoA) technology.

This choice also came with a comprehensive software stack to enhance their solutions and the industry-leading security features with our Secure Vault™, the most advanced level of security features.

The article was originally published as a Silicon Labs Case Study.